One-Step SDS Removal Kit

- Stock: In Stock

- Model: 0144

Available Options

Introduction

Sodium dodecyl sulfate is one of the most used detergents for solubilizing biological materials. Still, excess unbound detergent interferes with many downstream applications like mass spectrometry (MS) and amino acid sequencing, antigen-antibody binding, immunoprecipitation assay, and ELISA. Several SDS removal protocols, such as prolonged dialysis, anion exchange chromatography, spin column, and acetone precipitation, are routinely used. However, these procedures are either laborious or suffer from sample losses and are challenging for low volume samples and high thorough-put automation. We developed a novel, efficient SDS removal system to overcome these limitations.

Hygia One-Step SDS Removal Kit uses magnetic beads modified with proprietary chemistry to remove SDS detergent. The resin can quickly and efficiently remove free SDS (sodium dodecyl sulfate) from ultra-low volumes of protein/ peptide or DNA/RNA solutions. The beads enable 96 samples to be processed simultaneously in less than 10 minutes.

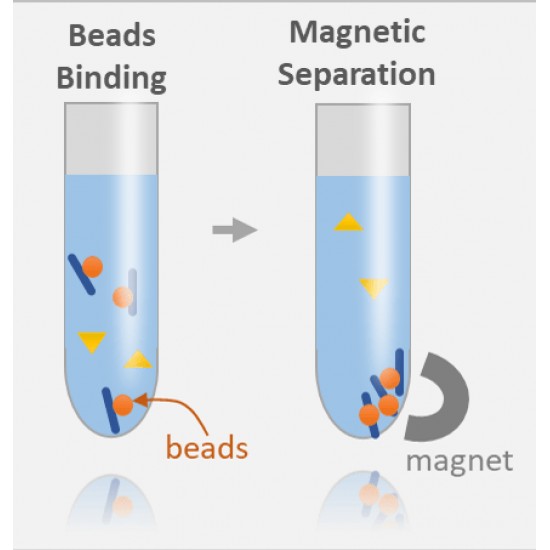

The beads allow rapid and efficient removal of free SDS from the sample. The procedure is straightforward. 1. Add the beads directly to the sample. 2. Pipette or vortex to capture the free SDS detergent. 3. Magnetic separation of the beads from the protein, or DNA/RNA solution, while the protein or DNA/RNA remains in the solution. The easy-to-use magnetic beads significantly improve results over the standard drip column and batch methodologies with minimum protein loss (<10%). Since only a small volume of magnetic beads is used, the final protein concentration of the sample is not significantly decreased.

Features and Advantages

● Simple protocol: No liquid transfer, One-tube, One-step, and one-minute protocol

● Easy-to-use

● Reliable and reproducible results with exceptional >90% recovery for protein (>6 kDa, aprotinin) or DNA/RNA (>25mer dsDNA)

● Effective Cleanup: Remove 95% free SDS detergent

● Cost-effective: Eliminates columns, filters, and laborious repeat pipetting

● High throughput: Compatible with many different automated liquid handling systems

1-250x250.jpeg)

1-250x250.jpeg)